Electric hoist and trolley systems keep factories humming, workshops moving, and ports turning. Vector Lifting specialises in tailored electric hoist and trolley solutions that meet the demanding needs of Australian industry. Our electric chain hoists blend power, precision, and durability to make lifting simpler, safer, and more reliable, while keeping your workflow smooth and compliant.

Standard Range TableOptions Available

- Capacity

- Standard or low headroom

- Power Supply 415V or 240V (for limited capacities)

- Single or 2-speed hoists

- Single or multi-fall chains

- Custom Control Pendants

What Is An Electric Chain Hoist?

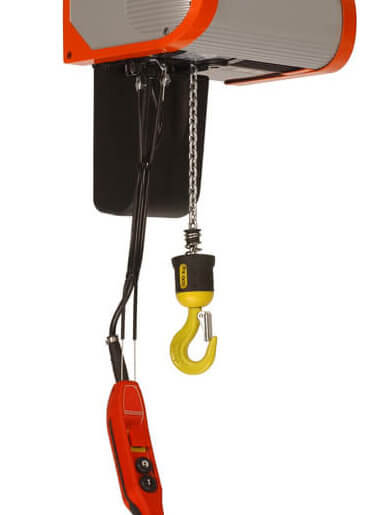

Electric chain hoists are powered lifting devices that use a chain to raise and lower loads, with very little manual effort. Think of them as a compact, motorised pulley, doing the heavy lifting so people do not have to. They are versatile, efficient, and a go-to choice for many indoor industrial tasks.

How Electric Chain Hoists Work

Here’s the thing. An electric motor drives the load chain through a block and tackle style arrangement, which gives accurate, steady lifting and lowering. Safety features are built in, like overload protection and emergency stops, so the kit behaves when things get testing. The mechanical layout is simple, which means maintenance is straightforward and the units can last a long time if you look after them.

Electric Chain Hoist vs Wire Rope Hoist

Wire rope hoists use steel cable and suit very heavy lifts or high headroom spaces. Electric chain hoists are lighter and more compact. They work better where clearance is limited, or when you need something less bulky indoors. Short version, chain hoists are ideal for light to medium loads, and wire rope is the go-to when the tonnage climbs or headroom is generous. You know what? Each has its place.

Key Features Of Electric Chain Hoists

Capacity And Configurations

Chain hoists come in a range of load capacities, from around 125 kilograms up to several tonnes. You can choose standard headroom or low headroom models to suit your ceiling height and layout. Multifall chain arrangements increase lifting capacity and spread the load more evenly when you need extra muscle.

Power Supply And Speed Options

These hoists are built to run on Australian power, typically 415V three-phase or 240V single-phase. Motor choices include single-speed and dual-speed versions, so you can pick smooth, precise control when required, or go faster when the job calls for it.

Design Variations And Controls

Control styles vary. You can have a simple pendant with clear on and off controls, or a more advanced remote that includes emergency stop, variable speed and wireless operation. Custom setups are common. Want a quiet buttoned-up solution, or something rugged for a dusty shed? It can be done.

Benefits Of Using Electric Chain Hoists

- Improved efficiency and higher productivity for lifting jobs.

- Safer operation with precise load and speed control.

- Compact design that fits tight indoor spaces.

- Low maintenance thanks to sturdy, durable components.

- Built to cope with harsh Australian conditions, such as dust and heat.

- Local support and ready availability of spare parts.

Applications And Industries Served In Australia

Vector Lifting’s electric hoists and trolleys are used across Western Australia and nationwide. They turn up in places where reliability matters and downtime is costly.

Mining Sector Usage

In iron ore, gold and bauxite operations, these hoists handle heavy loads and maintenance lifts. They need to be tough, and they are. Harsh environments, long shifts, and safety-first work, they cope with all of it.

Manufacturing And Maintenance Applications

You will find them in heavy maintenance workshops, on production lines and during plant shutdowns. They move components efficiently, reduce manual handling injuries and speed up repeatable tasks.

Ports And Offshore Handling

For gantry cranes, ports and offshore facilities, electric hoist and trolley systems deliver dependable, precise material handling. Salt, wind and long hours are part of the job, and the equipment is specified to match those challenges.

Why Choose Vector Lifting For Electric Hoists And Trolleys?

Australian Ownership And Local Support

Vector Lifting is 100% Australian owned and operates out of Western Australia. That matters. You get local knowledge, fast response and practical support when you need it.

Compliance And Custom Design Capabilities

Our hoists meet Australian Standards such as AS 1418, so safety and build quality are not left to chance. We also specialise in custom designs that suit your exact operational needs. Need something a little different? Tell us the problem. We’ll help solve it.

Comprehensive Services And Aftermarket Support

We cover installation, commissioning, routine maintenance and spare parts supply. Having someone who knows the gear and can keep it running is worth its weight in gold when production depends on it.

Contact Vector Lifting For Your Electric Hoist Needs

Make sure your electric hoist and trolley systems meet Australian standards and fit your operational needs. Contact Vector Lifting to talk through tailored solutions that enhance safety and productivity. Our local experts will guide you through product selection and provide reliable, personalised service across Western Australia and beyond. Use the contact form below to get in touch. Experience the difference of knowledgeable local support and quality products from Vector Lifting.